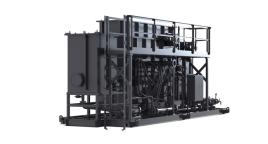

Industrial Water Filtration & Water Treatment Systems

Filtra-Systems designs and manufactures a vast array of industrial water filtration, wastewater treatment systems and filters and mobile water filtration systems for industrial water applications worldwide.

These industrial water filtration systems and water purification systems work within your applications cleaning produced water, wastewater, groundwater, cooling tower water, PFAS contaminated water, to name just a few. Learn how industrial water filtration can improve efficiency and save you money.

Because you have very specific manufacturing applications, we build custom-engineered filtration systems and stock a wide range of filtration systems.

Media selection & chemistry is an important step to successfully meeting environmental discharge guidelines or recycling wastewater for reuse in your process.

The availability of many diverse systems and filtration media gives you several strategies and options to help solve even the most complex wastewater issues.

Click here to get a few answers to common industrial filtration questions.

These industrial & commercial water filtration systems are frequently available and suitable for either short-term rentals or long-term installations. Rental systems are usually in stock and can often fit into your operational budget with no capital investment.

Contact us today and we'll assist you in obtaining simple-to-use industrial filtration systems that exceed your expectations.

Industrial Water Filtration Systems

Not sure what type of filtration you need or have questions about your equipment?

Ask our team of experienced applications engineers to review your application, process, and facility and make recommendations that will be best for your manufacturing, production and bottom line.

Additional Information

We're here to provide you the highest-quality industrial water filtration systems and industrial air filtration solutions.

These systems set you in motion with the tools for creating a custom solution that best fits your applications and goals.

We partner with you from the initial testing phases through the installation process. Partnering ensures that you get the ideal filtration solution.

Our team of filtration experts will always be there to assist you with almost any service you need for any of our systems.

We are ISO 9001:2015 certified and have many other certifications which you can find here.

Our dedication to providing you with the highest quality filtration systems has helped us grow for over 40 years, providing proven systems that promise to meet or exceed all your expectations.

Click below to learn more about our industrial water and industrial air filtration systems and to request your quote today.