Walnut Shell Media Filters

Don't overthink it, the Filtra-Systems walnut shell filter is the answer!

This straightforward solution tackles both oily process water and industrial wastewater with unmatched effectiveness.

Its ingenious walnut shell media acts like a magnet, attracting 95% to 99% of suspended solids and hydrocarbons, leaving you with water so clean it can be reused.

And the best part? No chemicals are required!

Plus, it boasts a >99% uptime record and skips the chemical hassle. Problems are solved naturally and with powerful results.

How it works:

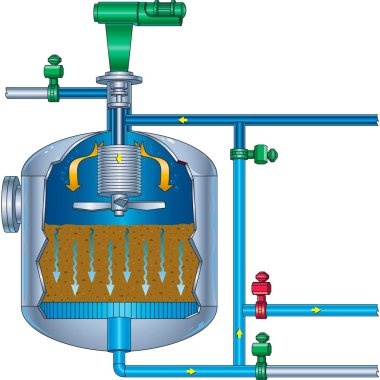

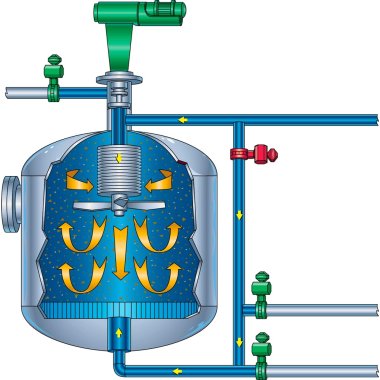

As the liquid passes through the walnut shell media filter's media bed, oil and solids are efficiently retained in the bed and can easily be backwashed out of the media bed with the patented rotating media scrubbing assembly.

These backwash assemblies are proven to be the best technology available for fluidizing the media bed and allow the manufacture of large flow horizontal units.

Even better, neither of the following is required for the backwash:

- No chemicals

- No surfactants

- No air sparging cycles

Click here to discover the many advantages of a walnut shell media filter

Description

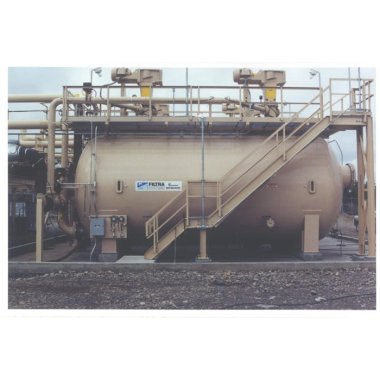

Filtra-Systems' innovative STiR Deep Bed Nut Shell Media Filter has overcome the limitations of conventional bed-type industrial water filters by leveraging a maximum efficiency regeneration design.

This media regeneration in our walnut shell filter is achieved using the kinetic model of a Continuous Stirred-Tank Reactor (CSTR).

The CSTR makes backwashing

- The most efficient

- The most powerful

- The most economical

It is the only scientifically proven regeneration technology offered on the market today.

Why Filtra Systems?

Designing & building solutions for customers and listening to their feedback for decades has made us the leading walnut shell filter system manufacturer.

With over 40 years of experience in industrial water and wastewater filtration, we've engineered, built, and field-tested solutions for customers in a very wide variety of industries.

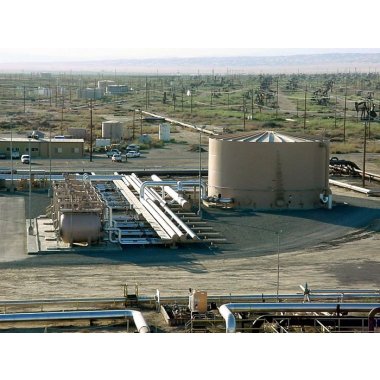

The Deep Bed Walnut Shell Filter is a proven technology with hundreds of installations worldwide, in a variety of difficult applications.

Rental Systems are available. And, frequently, they fit into your operational budget. No Capital Investments.

When your sand, anthracite, or multimedia industrial water filter system stops backwashing properly, the Walnut Shell Filter will do the job, 100% guaranteed.

Operation

In high-volume water and wastewater filtration applications, Deep Bed Nutshell Filters are used to remove suspended solids and insoluble hydrocarbons from oily wastewater, groundwater, plant process water, cooling water, and water recycling and reuse.

In metalworking, power generation, chemical, and petrochemical applications, these industrial water filters treat and remove suspended solids, oily residues, ash, and metallic hydroxides from industrial liquids.

Deep Bed Walnut Shell filtration systems give you double the throughput efficiency of conventional sand or graded mixed-media filters for the removal of suspended solids and hydrocarbons.

Under normal operating conditions, they remove 95 to 99% of suspended solids and 90 to 99% of insoluble hydrocarbons without the use of chemicals.

This unparalleled efficiency makes the Walnut Shell Media Filter one of the best industrial water purification systems on the market today.

Click here to discover why a walnut shell media filter is a great option for you.

Product Range

- High throughput nutshell filters for the purification of oily process water and industrial wastewater.

- Single filtration units are available up to 5,000 GPM (175,000 BWPD).

- Deep Bed Nutshell Filtration Systems give double the throughput of conventional deep bed sand or graded mixed-media filters. Horizontal and vertical models are available for flexibility.

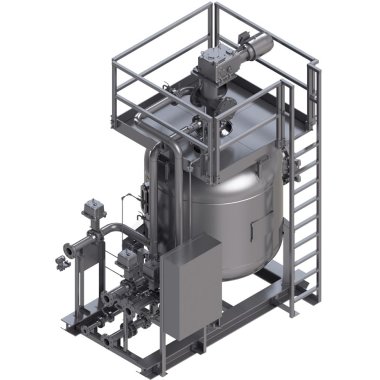

- We offer ten (10) standard vertical and six (6) standard horizontal Nutshell Filter models.

- Vertical models provide a flow rate range from 70 GPM to 2800 GPM per unit, while horizontal models provide flow rates from 1200 GPM to 12000 GPM per unit, depending on the application.

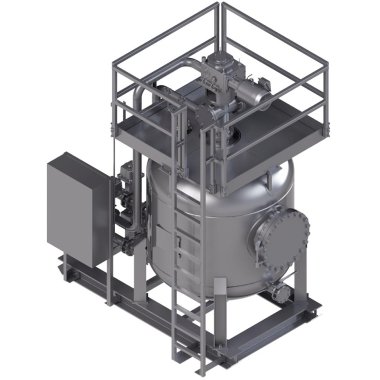

- Units are pre-assembled at the factory and can be shipped to the job site skid-mounted, ready for installation. Also, larger sizes can be custom-designed to meet your specific project needs.

Features and Benefits

- Unique to the Deep Bed nutshell industrial water filters is a patented media scrubbing cycle that fully regenerates the media filtration system during each backwash cycle.

- This scrubbing cycle is initiated automatically whenever the filter bed becomes dirt-laden.

- A change in the pressure differential across the filter bed or an automatic preset time signal activates backwashing.

- The current Walnut Shell media design incorporates the high intensity of a mixer to vigorously agitate the media bed during the scrubbing cycle.

- The mixer is combined with the separating efficiency of a rotating backwash scrubber screen to produce the optimum separation of the scrubbed media from the concentrated backwash fluids.

Industry Applications

Our Walnut Shell Media Filter Systems can be used in a variety of different applications including:

Not sure what type of filtration you need or have questions about your equipment?

Ask our team of experienced applications engineers to review your application, process, and facility then make recommendations that will be best for your business.

Explore Related Featured Projects

Below you will find some projects that have benefited from our technology.