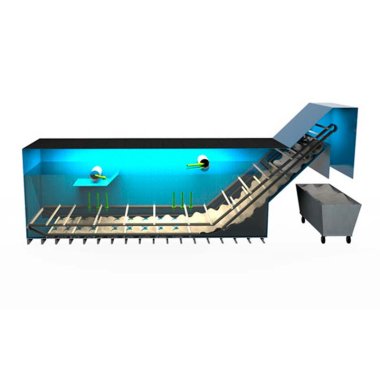

Central Coolant Filters & Filtration Systems

Filtra-Systems' position as a worldwide leader in industrial filtration systems means that we have worked with thousands of customers to create custom filtration solutions for their needs.

Because we have designed and built custom systems for clients in many industries, we understand different solutions work better for certain applications.

This is precisely why we offer different types of central coolant filters and filtration systems to fit the needs of our customers, including vacuum, pressure, gravity, magnetic, and bag filters.

Our central machine tool coolant filtration systems are designed to provide coolant filters and complete central coolant filtration systems that perform at the optimum pressure, flow rate, temperature, and clarity required for each operation.

Custom Design & Engineering

Every central coolant filtration application that a customer has is different.

Our extensive industry experience, broad clientele, and over thirty patented products help to deliver custom, optimized central coolant filtration systems for our customers that are easily integrated into their operation.

These various central coolant filter projects that we have worked on over the years allows us to offer you the broadest line of equipment in the industry and handle applications form 50 gpm to 50,000 gpm for every type of machining operation and cutting fluid.

Central water filtration systems are used for production machining applications that require multiple machines for each operation.

Your central coolant filtration system can be designed around any one of our coolant filters and has the advantage of providing each machine with the same concentration of coolant, at the same temperature, and pressure.

All metal fines are discharged in one location and the need to operate and maintain multiple coolant filters is eliminated. Operating and maintenance costs are reduced and product quality is enhanced.

Not sure what type of filtration you need or have questions about your equipment?

Let our team of experienced applications engineers review your process to access your needs and make a recommendation that will be best for your business.

Explore Related Featured Projects

Below you will find some projects that have benefited from our technology.