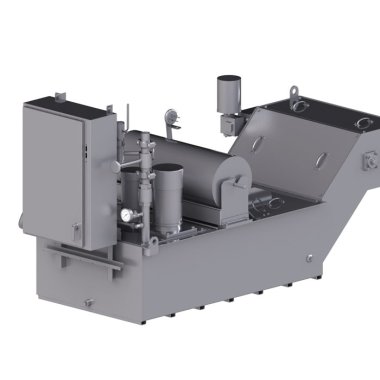

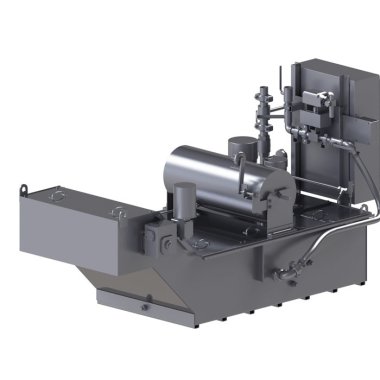

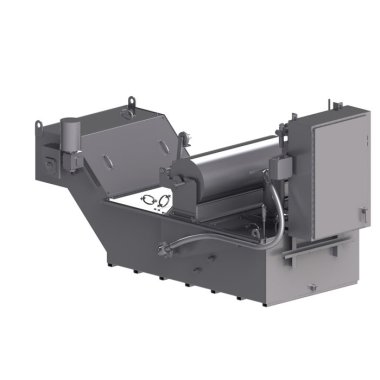

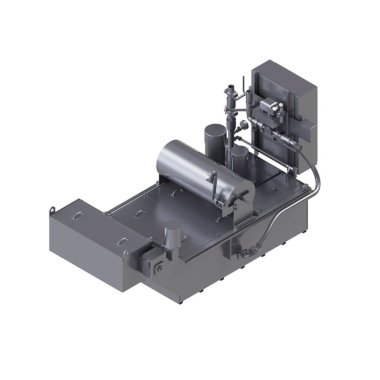

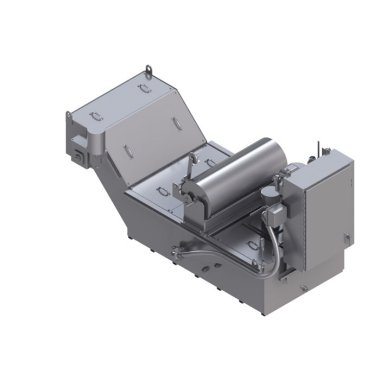

Portable Oil Filtration: Mini-Vac-MV

The Mini-Vac is a proven compact portable oil filter system for removing your solid contaminants from water-soluble oils, synthetic coolants, mineral seal oils, and heavier cutting oils.

Description

Its compact, self-contained design provides you easy installation in confined areas.

And, the wheel-mounted Mini-Vacs can be easily rolled anywhere in your plant to clean the average machine sump quickly and effectively.

This level of filtration efficiency has been proven to double or triple machine tool life while extending the life of the cooling and tooling.

Contaminated liquid from machines is either pumped or drained into the Mini-Vac filter reservoir. Next, velocity and gravity draw liquid down to the filter media, where solids are retained.

Operation

Clean liquid is drawn through the filter medium at the bottom of the dirty reservoir by the Mini-Vac pump.

From the clean liquid vacuum chamber, the liquid is continuously pumped to the machines.

Automatic operation is controlled by a pre-programmed filter cycle; media is rotated when a pre-set vacuum is reached.

The flight conveyor and disposable filter media move a predetermined distance, usually a couple of inches. During the short index cycle, the liquid is drawn from a reserve tank to ensure a continuous supply to machines lubricating fluids indefinitely.

Product Range

With flow rates from 5-350 gpm and operating vacuum up to 15" Hg, Mini-Vac industrial oil filters can handle virtually any size machine tool. Fines down to 1 micron are removed.

Features and Benefits

- Small footprint

- Economical

- Versatile... can be moved with your equipment if floorplans change.

- Has a variety of pre-engineered options to tailor build your unit for your specific applications.

Not sure what type of filtration you need? What questions do have for us?

Let our team of experienced applications engineers take a look at your process to evaluate your needs and make recommendations that will be best for your applications, facility and business goals.

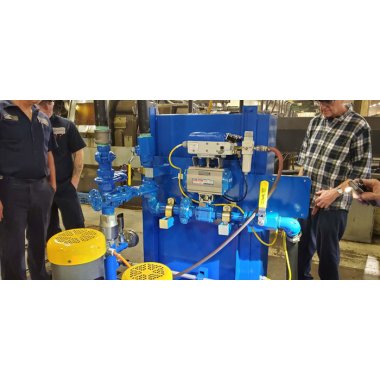

Explore Related Featured Projects

Below you will find some projects that have benefited from our technology.