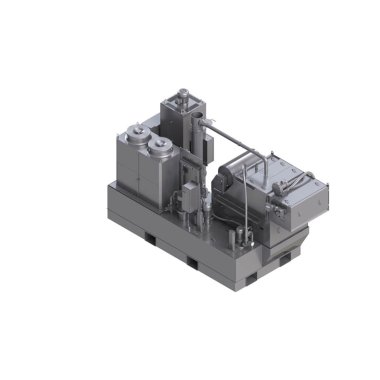

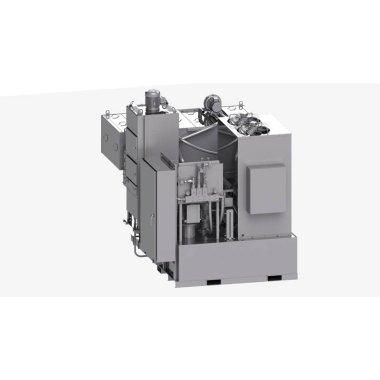

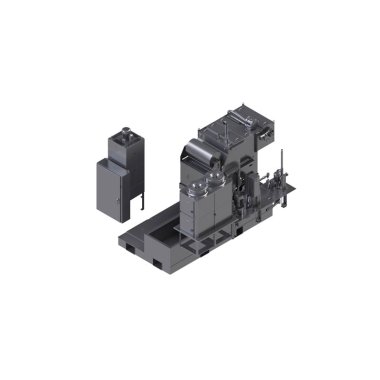

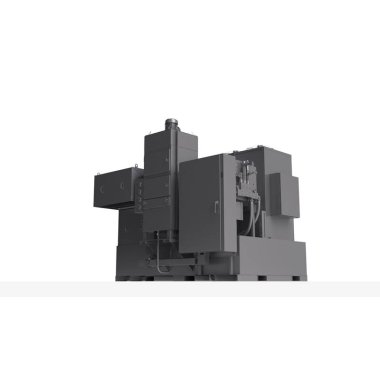

PV50—CNC Fluid & Mist Filtration System

The PV50 filtration system is designed to achieve the required metalworking fluids (MWFs) clarity for typical CNC high-speed gear grinding, fine grinding and polish grinding applications.

These individual filtration modules have a small footprint and can serve as your primary filter or as a host for several modular options to fully support your machine in a variety of utility options.

These units have a permanent belt filter developed to support and filter metal cutting operations that are focused on, but not limited to, grinding and honing.

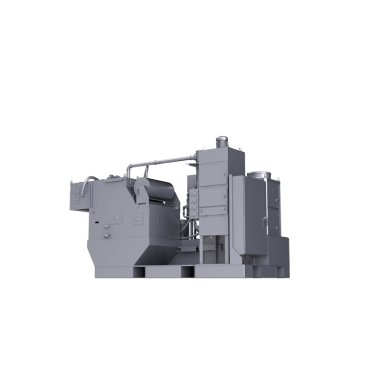

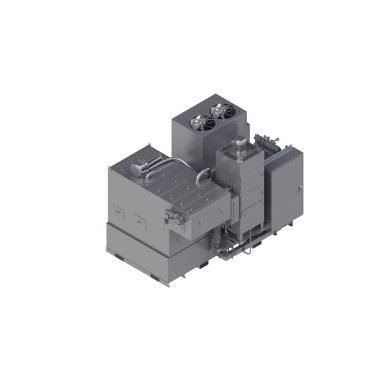

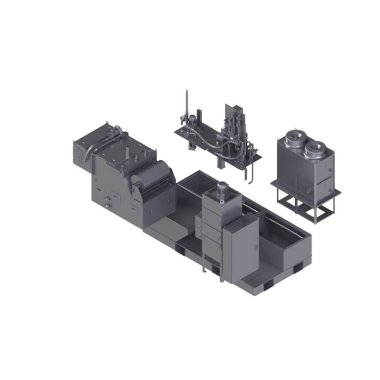

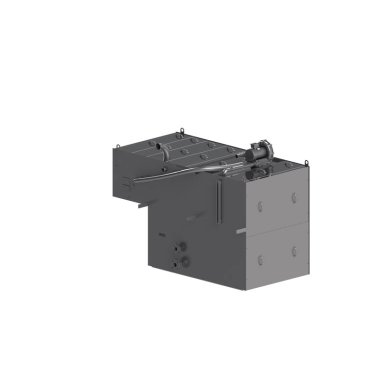

The PV50s come equipped with the capability to run with a permanent belt only or single-use media. Both can be used together to increase belt life and filtration efficiencies.

The swarf is discharged after being incrementally indexed from the filter module through the cake drying section (coolant removal process).

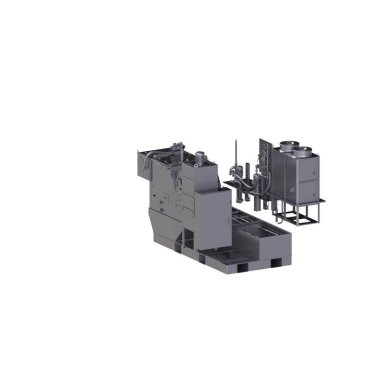

Coolant control valves and pumps are included in the clean tank to deliver the cutting fluid to the machine at the required pressure and flow.

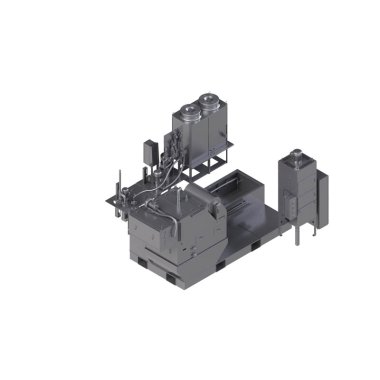

The PV50 is guaranteed to provide the necessary cutting fluid clarity for high-speed gear grinding, fine grinding, and polishing grinding. Most machining applications, for example, produce fine chips.

Description

The PermaVac (PV50) filtration module is designed to achieve the required oil clarity for high-spread gear grinding, fine, and polish grinding applications.

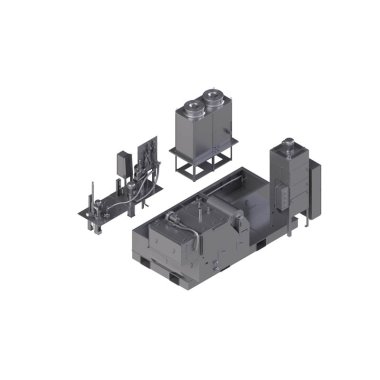

The standard PV50 filter comes with the capability to only run with a permanent belt. This permanent belt will limit the maintenance of replenishing or disposing of disposable media.

Single-use media can be used together when the operation needs the increased demand for tighter filtration efficiency during the dressing or fine grinding operations.

A dry swarf section is included in the head section of the module helping the filter remove as much of the valuable oil as possible before discharging it into the cart for reclaim or disposal.

Operation

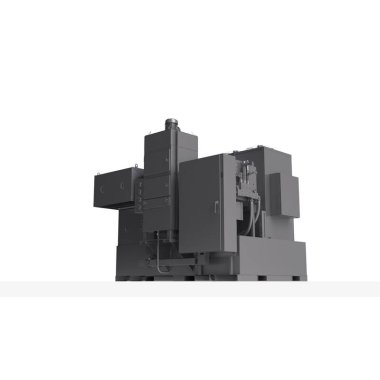

The PV50 module has a simple inlet connection that ties into the module.

Single-use media rolls can be equipped at the rear of the filter for easy maintenance and replacement.

The filter discharges the swarf and is captured by the permanent belt after it is completely dried.

The dry swarf is discharged into a reclamation bin or hopper for proper disposal.

Product Range

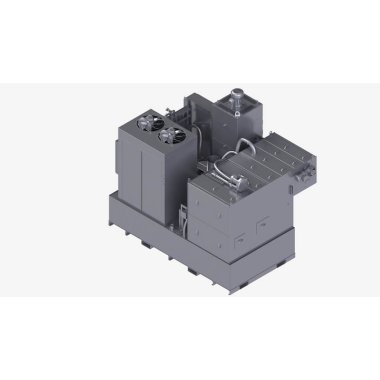

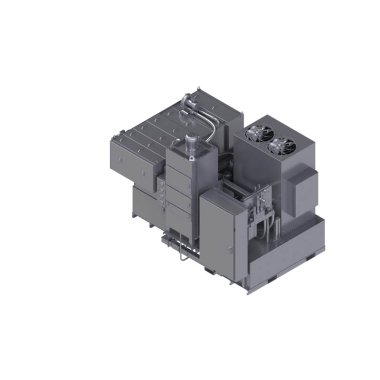

The PV50 has several options available when selecting the equipment that is right for you.

The base module can be the base platform in which you can customize your equipment.

Optional mist collection, valve automation, fluid temperature controls, spindle temperature controls, and many other utility options are designed and available to assist your machine tool as an external support system.

Features And Benefits

- Small footprint for integration into tight layouts.

- Filtration Section which utilizes either permanent or disposable media

- Drying Station which removes as much oil as possible from the filtered swarf prior to discharge

- Wide range of flow rates and pressures capable for almost any machine requirement.

- Global support and responsive service

- Stocked spare parts and consumables.

- Optional CNC Machine Tool Supply Pumps

- Optional Stealth/Eliminator Mist Collector and Coolant Recovery

- Optional Spindle and Cutting Fluid Chiller

- Optional PLC Control Panel, to provide the CNC machine tool with a single operator interface

- The PV CNC coolant/oil filter can provide machine tool manufacturers a standalone, turnkey liquid, oil and air filtration management system.

Industry Applications

Our PV50 CNC Filtration Systems can be used in a variety of different applications including:

Not sure what type of filtration you need or have questions about your equipment?

Let our team of experienced applications engineers review your process to evaluate your needs and make a recommendation that will be best for your application, facility and business.

Explore Related Featured Projects

Below you will find some projects that have benefited from our technology.