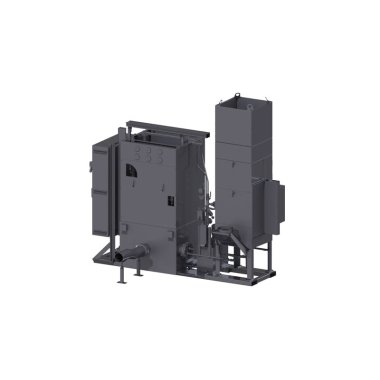

Machine Tool Utility Skid

Machine tool utility skids are a dynamic piece of equipment that offers several support functions to the operation of your CNC machines.

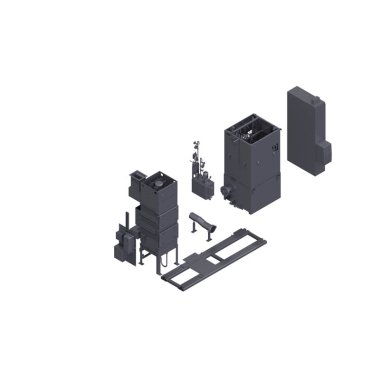

Designed to have many applications and several interchangeable parts; the utility skid is not one piece of equipment but several all tied together under a single user interface.

Description

- Filtra-Systems' machine utility stations offfers a platform to help solve a variety of problems including, clean fluid automation, dirty coolant transport, mist collection air quality, and spindle chilling (or) any combination

- Incoming Clean Fluid – Onboard pressure boosting pumps supply machine tools with cutting lubricant at a desired pressure and flow rate. This is in a response to a central filtration system supplying multiple machines that operate under different pressure parameters. These boost pumps increase the supply pressure provided by the plant to the proper requirement.

- Automation – After the pumps have properly boosted the pressure valve automation can be added so that the manifold is linked to the boost pumps. This automation delivers clean fluid to the equipment at the desired location and frequency initiated by the machines programmed cycle.

- Mist Collection – In wet operations that have high pressure or high-speed cutting applications producing uncontained mist. Keeping your operators in a safe air environment a Stealth mist collector can be the perfect addition.

- Pump Back – The pump back can be added to the skid as well to provide a tank to collect the dirt-laden cutting fluid. This tank will pump back to the plant filtration systems

Operation

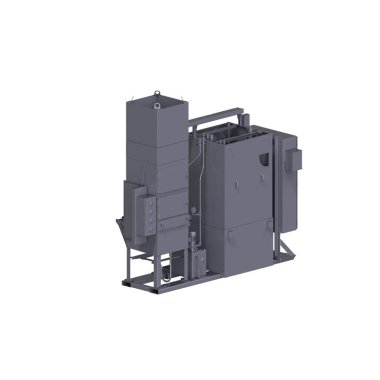

The operation of the skid can vary depending on the options selected for the process.

All options can be tied together back to a single operating interface that saves time on integration and operation.

Features And Benefits

- Single engineering contact and a single point contact for a multiple support systems that can be integrated into a single machine.

- Reducing design and providing a variety of tools making the equipment more nimble to movement within the facility.

- Ability to customized per operation with low pressure, high pressure, spindle chiller, mist collection, valve control automation.

Industry Applications

Our Machine Tool Utility Skids Systems can be used in many different applications including:

Not sure what type of filtration you need or have questions about your equipment?

Let our team of experienced applications engineers review your process to determine your needs and make a recommendation that will be best for your application, facility and business.

Explore Related Featured Projects

Below you will find some projects that have benefited from our technology.