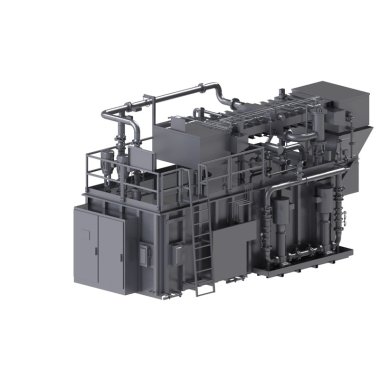

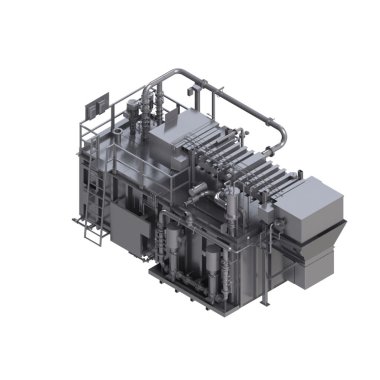

Pressure Filtration System

Our pressure filtration system uses a methodology that pumps or pushes the fluid through vertical pressure filters that remove sediment and debris.

In short, our pressure filtration systems are fully automatic dewatering pressure filters that are typically used to separate solid products from the slurry, wash the product to remove impurities, and then dry and automatically discharge the product.

Take a look below and for more details...

Description

- The Verti-Press Filter is the new generation of Automatic Pressure Filtration technology, used for filtering and dewatering industrial and municipal wastewater applications.

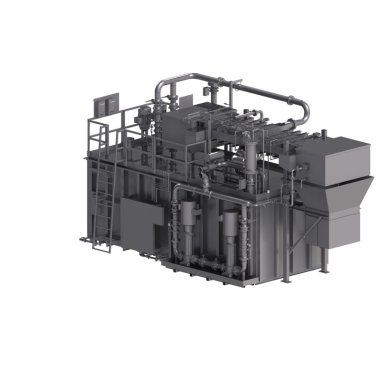

- The pressure filtration system uses patented pneumatic seals to seal the chamber off during filtration (no more clamshell opening and closing). Once filtration is complete, compressed air forces the remaining liquid through the filter media, which removes contaminants from the cutting oil.

- Next, the filter media is automatically discharged from the automatic pressure filter after each filtration cycle.

- The Verti-Press is typically constructed out of carbon steel to minimize cost and still allows for a robust pressure filter design.

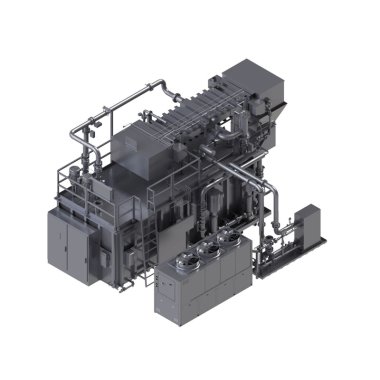

- The units are used in the metalworking and steel industries for filtering contaminants from coolants, oils, and wash water applications.

Operation

The horizontal chamber in this pressure filter design ensures an even filter cake formation and allows for the Verti-Press units to be stacked, one on top of the other to minimize the footprint.

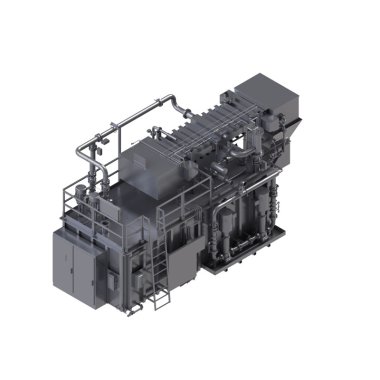

Another benefit of these automatic pressure filters is, in multiple chamber installations, chambers operate independently and can be isolated to maximize run times.

Features And Benefits

- Patented pneumatic seals to enclose the filter chambers instead of the clam shell open/close

- Enclosed chamber increases plant Hygiene/Safety

- Even cake formation maximizes removal and operating efficiencies

- Multiple chambers units can be isolated, thereby allowing maximum run times

- Minimum moving parts: small footprint and vertical chamber installation

- Fully automated with PLC and HMI controls

- High flux rates leading to higher production rates

- Sub-micron filtration

Videos

Industry Applications

Our Pressure Filtration Systems can be used in a variety of different applications including:

Not sure what type of filtration you need or have questions about your equipment?

Let our team of experienced applications engineers review your process to determine your needs and make recommendations that will be best for your applications, facility and bottom-line.

Explore Related Featured Projects

Below you will find some projects that have benefited from our technology.