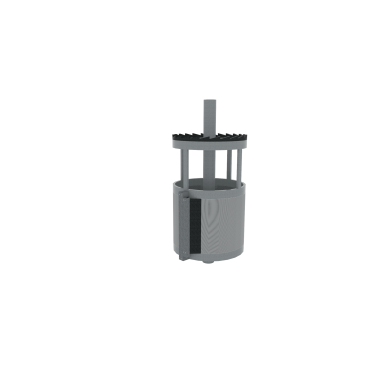

Rotary Vacuum Drum Filtration System

The rotary vacuum drum filtration system is a permanent rotating cylinder that is constructed of Filtra Systems PermaFlow technology or wedge wire that acting as a filtration septum.

This rotating cylinder collects the contaminates from the fluid and quickly conveys them out during a fully automated cleaning cycle; all while offering a completely green and maintenance-free solution.

Description

The Perma-Flow is the Filtra-Systems rotary indexing micro screen vacuum filter which offers a number of benefits in machining applications.

The Perma-Flow offers strainer type separation with a unique pressurized incremental backwash system and scraper for positive cake removal and conveyance system.

Fine filtration of fewer than ten microns is a reality with the Perma-Flow rotary drum filter, and its modular design provides for parallel operation on large systems, or total spare capability.

Operation

The PermaVac operates with a patented vacuum placed drum in the main filter tank. This drum is designed to build up a cake on the external surface with no aid of conventional paper media. Once the operations reach a predesigned limit the system initiates a self-cleaning cycle that continuously runs while the machine is in operation. The heavy particulate falls from the filtration drum and is collected at the bottom of the filter tank where it is conveyed out of a single discharge point for easy collection and removal.

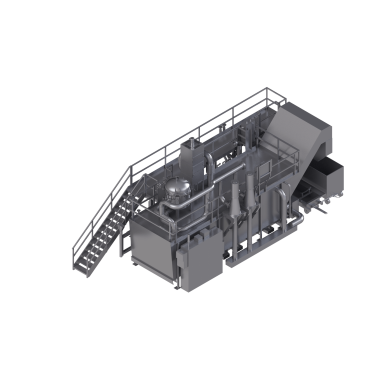

Product Range

These drum screen filter units are available with 3.5 square feet of filter area up to 140 square feet per unit, for a custom match to your application.

Features and Benefits

- Low landfill disposal costs

- Continuous cleaning conveyor

- A complete catalog of Accessories and Expansion Capabilities Temperature control, Secondary filtration for super clean operations, Magnetic Filtration, Mix metal filtration, Mist Collection

- Stainless steel micro-screen septum

- Patented Cylinder I.D. and O.D. Screen Doubles Filter Area Per Unit.

- All drive components are mounted in the top of the rotary drum filter, above liquid level, allowing visual inspection of drive.

- Patented Incremental Backwash

- Continuous, Fully Automated Operation of Rotary Drum Screen Filter

- No Clean Tank Required

- Compact and Modular (95%) Cake Retention Increase Coolant Clarity During Index

Industry Applications

Our Rotary Drum Filtration Systems can be used in a variety of different applications including:

Not sure what type of filtration you need or have questions about your equipment?

Let our team of experienced applications engineers review your process to access your needs and make a recommendation that will be best for your business.

Explore Related Featured Projects

Below you will find some projects that have benefited from our technology.