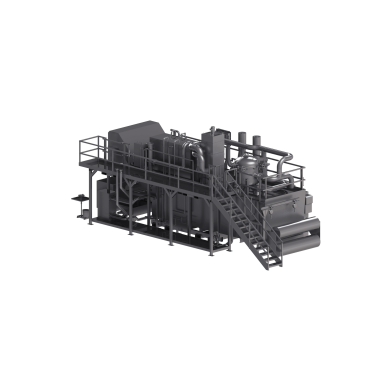

Metal Cutting Vacuum Filtration

Our metal cutting vacuum filter system is a robust and tested tool used for filtration.

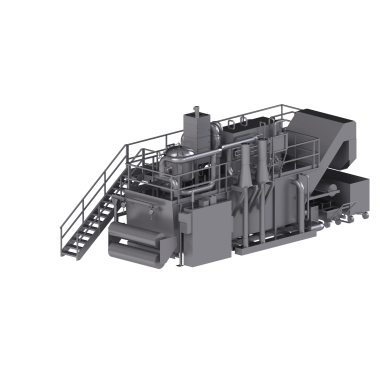

Filtra has developed a large product line that comes in various sizes to fit almost any solid-to-liquid separation operation.

This highly modular platform can support individual machines or in large applications. A central filtration system can support up to 60 machines running simultaneously.

Description

Filtra-Systems' Hydro-Vac is the "original" metal cutting vacuum filter system for metalworking liquids.

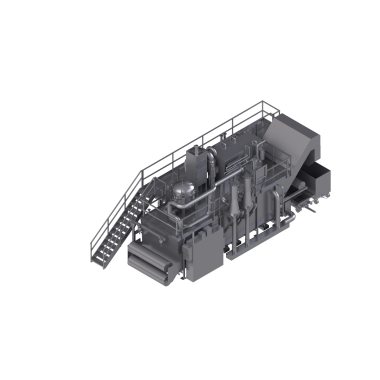

Founded in 1979, our company's position as a global leader in coolant filtration means that we have installed more than 6,000 Hydro-Vac systems around the world.

As a result, companies in a wide range of industries rely on our vacuum filtration system to keep their operation running smoothly.

Having been put to the test in real-world settings thousands of times over, we always stand behind every system with a worldwide sales and service network that solves problems and stocks spare parts and filter media.

Operation

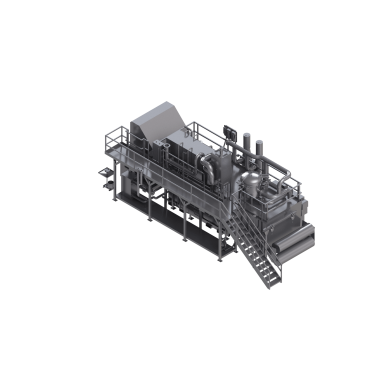

Vacuum filtration focuses on pulling your dirty effluent through a filtration medium in order to remove the solids that are trapped within the fluid.

This process is fully automated within the HydroVac to ensure no downtime or pause for cleaning or removing waste.

Automatically monitoring the fluid for key performance indicators causes the system to react to increasing efficiencies to downstream equipment.

Product Range

With every filter serving a slightly different purpose, our applications engineers and system designers work with you to tailor these vacuum filtration systems to fit the specific needs of your operation.

Our laboratory can also execute preliminary testing to ensure that the right system and filter media is selected for your application.

An industry-tested product paired with world-class customization and support is what separates the Hydro-Vac from other competitors.

20-5,000 GPM

Features and Benefits

Features:

- 2 or more machines promote higher reliability and uptimes because of the redundancy in automation more depth of product offerings ensures reliability and uptime meets demand high demand.

- Complete Catalog of Accessories and Expansion Capabilities

- Temperature control

- Secondary filtration for super-clean operations

- Magnetic Filtration

- Mix metal filtration

- Mist Collection

Benefits:

- Extended tool life - By removing contaminants from cutting fluids and coolants, the HydroVac can help to extend the life of cutting tools and machine components, reducing the need for frequent replacements.

- Improved part quality - Clean cutting fluids and coolants can help to improve the quality of machined parts by reducing the risk of defects caused by contaminants.

- Reduced machine downtime - HydroVac can help to reduce machine downtime by maintaining the performance of cutting tools and machine components, reducing the need for maintenance and repairs.

- Improved machining efficiency - Clean cutting fluids and coolants can help to improve machining efficiency by reducing the amount of time required to achieve desired results.

- Lower operating costs - By extending the life of cutting fluids and coolants and reducing machine downtime, the HydroVac can help to lower operating costs.

- Reduced environmental impact - By removing contaminants from cutting fluids and coolants, HydroVac can help to reduce the environmental impact of metalworking operations.

- Improved worker safety - Clean cutting fluids and coolants can help to improve worker safety by reducing the risk of injury caused by contaminated fluids.

- Reduced risk of equipment damage - By removing contaminants from cutting fluids and coolants, the HydroVac can help to reduce the risk of equipment damage caused by abrasive particles or corrosive substances.

- Improved process control - The HydroVac can help to improve process control by providing a consistent supply of clean cutting fluids and coolants, reducing variability in machining results.

- Improved overall productivity - By improving the performance of cutting tools and machine components, reducing machine downtime, and improving machining efficiency, the HydroVac can help to improve overall productivity in metalworking operations.

Industry Applications

Our Vacuum Filtration Systems can be used in a variety of different applications including:

Not sure what type of filtration you need or have questions about your equipment?

Let our team of experienced applications engineers review your process to determine your needs and make recommendations that will be best for your application, facility and business goals.

Explore Related Featured Projects

Below you will find some projects that have benefited from our technology.